DIESEL AIR LIMITED

|

Engine

Overview: |

|

|

|

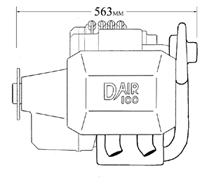

Diesel Air Ltd has designed and developed a |

|

Engine management with single lever

operation is greatly simplified with both carb heat and mixture controls

eliminated. The DAIR-100 will operate on diesel fuel or jet A1 and this with

the added reliability of liquid cooling (shock cooling avoided in the

descent) contributes to the low operating costs. The Diesel Air Two Stroke

Diesel has a power to weight ratio comparable with modern petrol engines. Why

delay. Switch to DIESEL. |

|

|

Operating

Principles Of The Opposed Piston Engine |

|

|

|

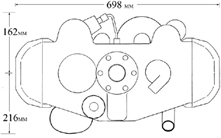

The twin cylinder opposed piston

engine has two pistons in each cylinder with the combustion chamber formed

between the crowns of the pistons. It eliminates the need for a cylinder

head, camshaft and associated valves and has in effect two half length crankshafts

linked by a gear train driving a centrally mounted propellor. The cylinders

are ported at each end with one ring of ports opened by the air piston

supplying the fresh air charge, and the other opened by the exhaust piston

and connected to the exhaust system. |

|

Gas flow through the cylinder is in

one direction (uniflow) and leads to more efficient scavenging, the name

given to the gas exchange process, than is normally achieved in a convential

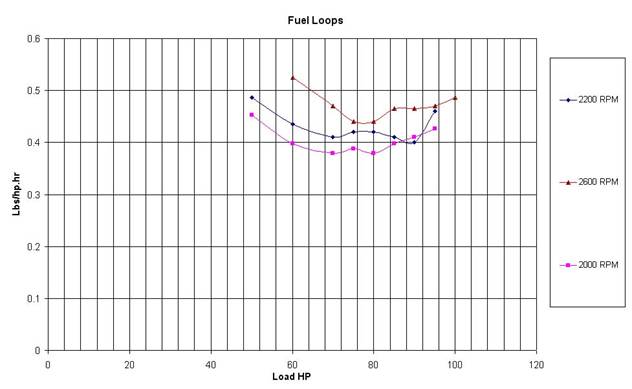

loop scavenged engine. The DAIR-100 has a centrifugal compressor supplying

this scavenge air which also provides a degree of supercharge improving

engine power. Power can be increased further with the installation of a

conventional exhaust gas driven turbocharger in series with the compressor.

Lubrication is by high pressure oil with dry sump and feeds plain main and

connecting rod bearings. Fuel injection is by hydraulically governed

mechanical pump feeding injectors in each cylinder. |

|

|

Technical Data: |

||

|

|

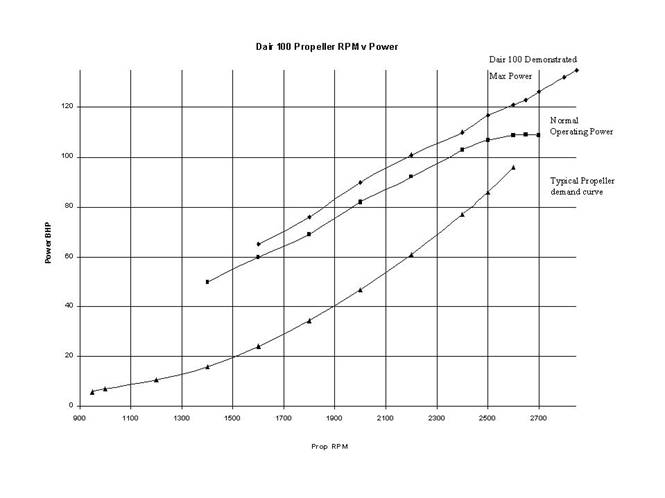

NUMBER OF CYLINDERS............ NUMBER OF PISTONS................ NUMBER OF INJECTORS............ BORE...................................... STROKE................................... DISPLACEMENT........................ COMPRESSION RATIO............... DRY SUMP CAPACITY................ FUEL GRADE............................ ENGINE MOUNTS...................... DRY WEIGHT........................... INJECTION SYSTEM.................. CONTROL................................ RATED RPM (Propellor)............. POWER................................... ALTERNATOR........................... STARTER

................................ PROPELLOR FLANGE................. |

2 4 4 80mm 90mm 1810cc 18 : 1 5 Litres AVTUR / DIESEL 4 POINT 92.7 Kg DIRECT SINGLE LEVER 2500 100 HP 12V / 20a (Optional 12V / 60a) 12 volt SAE 1

/ ARP |