After

2 years of experiments we have developed reasonably priced four stroke power

plants for light aviation. More than 12 years of experience in converting the

auto engines for racing in Poland, we have gained great knowledge of engines

and with young team of engineers 2 years ago we decided to provide aviation

community alternative auto engines for aviation use.

We chose Suzuki engines because

of their compatibility, light weight, all aluminum construction. These engines

are produced in today's cars and are available in any quantity. By choosing

current production engines we have eliminated the worry of our customer about

spare parts, if some things goes wrong with our company, you can buy all over

the world spar parts for these engines. So we really do not need to establish

web of our distributors all over the world to provide service, any authorized

auto-shop in the world can handle this.

RELIABILITY AND EFFICIENCY

Auto industry have billions of

dollars of funds for research and development purpose and then they have very

tough competition with each other. So we believe that these engines are far

more superior in quality, performance and in technology than aircraft piston

engines. Then they are very fuel efficient thanks to water cooling and auto

fuel is 1/2 the price of Avgas.

MODERN TECHNOLOGY

All new modern engines are

water cooled having following benefits over air cooled engines

okwater cooled engines add few

more components but:

- They burn about 12 to 15

%less fuel than air cooled engine ,which means your endurance will be more with

water cooled engine or less mtow.

Pls note that MR.RUTAN ordered

specially for his around the world flight water cooled engine from continental.

Without that modification that flight with out refueling was not possible. He

would have been simply run out of the fuel.

- Water cooled engine works at

constant temperatures maintained by thermostats, regardless of altitudes, power

settings and air temperatures.

- Controlled temperatures means

tight internal clearance of the components, adding more efficiency and

reliability of the parts.

- Cabin heat can be provided

with out the risk of carbon monoxide poising. Which is associated with air

cooled engines where the heat is drived from the hot burning gases.

INNOVATIVE FEATURES

- Customized fuel injection

system to compensate for the temperature and atmospheric pressure differences

at different flying altitudes

- Integral toothed Gear

Reduction Drive with anti tensional resonance device to counter the shock loads

to the propeller

- Customized lightened fly

wheel

- 1000 hrs TBO

- Any reduction ration

available

- Flat positioned engine to fit

almost all the engine cowls containing Rotax or Jabiru, or HKS engines

- Very reasonable priced

- Spar parts available all over

the world

Diffusion

After great increasing demand

of our power plants. To meet the production dates and delivery schedules Bilsamaviation

has joined hand with legendary polish auto engine converter for racing and

producer of sports cam shaft producer magistrate

engineer. Mr. Lech Swiatek and his team.

this diffusion will enable us to increase our production volume and at the same

time Mr. Swiatek has taken the responsibility to make further improvements.

Here are the details:

1) all customers will get turn key

engines, which means all the wiring and all the harness are preinstalled with

all the engine instrument's sensors and senders

2) carbon fiber exhaust

3) carbon fiber manifold

4) carbon fiber oil sump

5) new light weight and better reduction

unit

6) increased hp for L-S 1300(now 120hp)

7) more better and favorable torque

curves ,thanks to new designed cam shaft

8) increased hp for the L-S 1300 now 100

hp and 120 hp versions at lower RPM's with help of new cam shaft and other modifications

9) guaranteed deliveries of up till 15

to 20 engines per month

10) complete fire wall forward packages

with engines mounts for following aircrafts from january 2004

a) sky ranger

b) cosmos trike

c) air creation trikes

d) zodiac ch701

e) zodiac ch601

f) air trophy stool 2000

and of course al bilsam flying

machines

L-S AERO ENGINES TECHNICAL INFORMATIONS

|

ENGINE MODEL |

|

L-S 1000 |

|

L-S 1300 |

|

L-S 1300XP |

|

Cylinders |

|

In line 3 cylinders OHC |

|

In line 4 cylinders, OHC |

|

In line 4 cylinders, OHC |

|

Cooling |

Water cooled |

Water cooled |

Water cooled |

|||

|

Displacement |

1000 CC (61 cm3 ) |

1300 CC (80 cm3 ) |

1300 CC (80 cm3 ) |

|||

|

Power output |

80HP @ 5900RPM |

100HP @ 6000RPM |

120HP @ 6000RPM |

|||

|

Maximum torque |

100.9NM @ 4722RPM |

130NM @ 4800RPM |

135NM @ 4800RPM |

|||

|

Bore |

73,9 mm |

73,9 mm |

73,9 mm |

|||

|

Stroke |

76,9 mm |

76,9 mm |

76,9 mm |

|||

|

* All up weight |

78,6 kg |

72,5 kg |

89,7 kg |

|||

|

Reduction ratio |

2,40:1 |

2,40:1 |

2,40:1 |

|||

|

Ignition |

Electronic Ignition |

Electronic Ignition |

Electronic Ignition |

|||

|

Alternator |

30 Amp |

30 Amp |

30 Amp |

|||

|

* Full consumption |

10 liters |

12 liters |

12 liters |

|||

|

Fuel system |

Multi port fuel injection |

Multi port fuel injection |

Multi port fuel injection |

|||

|

Compression ratio |

10:8 |

10:8 |

10:8 |

|||

|

Firing order |

1,2,3 |

1,2,3,4 |

1,2,3,4 |

|||

|

Advance angle |

10° BTDC |

10° BTDC |

10° BTDC |

|||

|

Electrode gap |

0,8 - 0,9 mm |

0,8 - 0,9 mm |

0,8 - 0,9 mm |

|||

|

Trans mission |

Toothed gear |

Toothed gear |

Toothed gear |

|||

|

Trans mission type |

Helical type gear with dynamic

vibration damper |

Helical type gear with dynamic

vibration damper |

Helical type gear with dynamic

vibration damper |

|||

|

Transmission oil / gear box |

SAE 85W90-API-GL4 |

SAE 85W90-API-GL4 |

SAE 85W90-API-GL4 |

|||

|

Transmission oil quantity |

0,35 liters |

0,35 liters |

0,35 liters |

|||

|

Lubrication system |

Wet sump (oil pump) |

Wet sump (oil pump) |

Wet sump (oil pump) |

|||

|

Lubrication oil type |

SAE |

SAE |

SAE |

|||

|

Cooling capacity |

4,5 liters |

4,5 liters |

4,5 liters |

|||

|

Fuel |

Minimum 98 octane |

Minimum 98 octane |

Minimum 98 octane |

ROUTINE MAINTENANCE FOR L-S 1000

AND L-S 1300

|

COMPONENTS |

|

CHECK |

|

RENEWAL |

|

Oil level |

|

Before every flight |

|

Every 100 hrs or, one year

period |

|

Coolant level |

Before every flight |

Every 100 hrs or, one year

period |

||

|

Oil leakage |

Every 150 hrs |

150 hrs |

||

|

Oil filter |

- |

Every 150 hrs |

||

|

Spark plugs |

- |

Every 150 hrs |

||

|

* Air Filter |

- |

Every 150 hrs |

||

|

Fuel filter |

- |

Every 150 hrs |

||

|

** Transmission gear box oil |

150 h |

|

||

|

*** Dynamic vibration damper

torque |

150 h |

|

* Not renew but

clean oil by using JR clean and change except oil leak

** Transmission do not

require oil level checking, or renewal except oil leak

*** Vibration damper must

be checked for elastic resistance by pulling propeller by hand with NO Running

ENGINE

REMANUFACTURING PROCEDURE

|

PARTS |

|

CONDITION |

|

Gaskets |

|

New |

|

Timing belt tensioner |

New |

|

|

Spark plugs |

New |

|

|

Timing belt |

New |

|

|

Piston rings |

New |

|

|

High tension cable |

New |

|

|

Starter |

New |

|

|

Pistons |

New |

|

|

Big end Biering |

Reconditioned |

|

|

Water pump |

Reconditioned |

|

|

Inlet value |

Reconditioned |

|

|

Exhaust value |

Reconditioned |

|

|

Distributor cap |

Reconditioned |

|

|

Oil pressure indicator |

Reconditioned |

|

|

Alternator |

Reconditioned |

|

|

Cam shaft |

Custom modified |

TUNING PROCEDURES FOR L-S 1000 AND

L-S 1300 AERO ENGINES

|

Cylinder head verification |

|

(i) Inlet and exhaust channels |

|

Cam shaft |

Sports cam shaft |

|

|

Inlet manifold |

One throttle sport inlet

manifold |

|

|

Exhaust |

3 in 1 sports carbon fiber

exhaust manifold |

|

|

Fuel and ignition system |

Multi port injection with

electronic ignition |

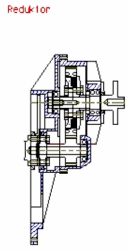

REDUCTION UNIT

Specially

hardened helical type toothed gear unit 25mm thick toothed wheels helical type

gear boxes are the best solution for low vibration and less noises which add

the components reliability and longer life we in cooperate special rubber

cushioned between the wheels to further improve the anti torsional effects of

whole system.

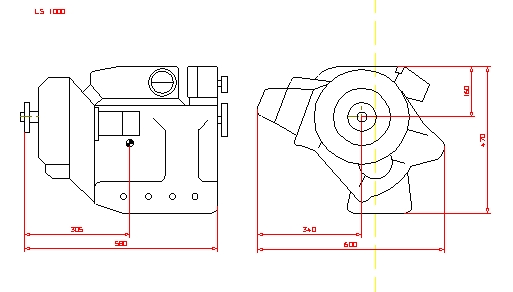

LS 1000 engine

The owners manual

1.General dimensions.

2.Details.

Origin of engine.

The base is Suzuki Swift G10 car engine.

Construction.

LS 1000 engine is predestined for ultralight aviation. Mega quality and

reliability of engine parts is guaranteed by origin from car industry. Engine

block and cylinder head are made of light alloy and this gives little weight.

Angle of inclination of engine is 20 degrees from level to close general

dimensions to boxer engines and secure little dimension between axis of

propeller and top line of engine.

Inlet manifold and oil sump are completely original constructions. They are

made of vinyl resins and strengthen by carbon fiber LS 1000 engine is feeded by

electronic fuel injection with electronic controller unit.

Reduction gear .

The helicoial gear with grinded teeth secure high reliability and

silent-running. It is equipped with dynamic anti vibration damper and separate

oiled.

3.Safety rules.

It is not allowed:

starting the engine without checking every flight operation and when routine

maintenance are not compete

starting the engine without propeller

starting the engine when any controller is not working

leaving the engine working

crossing maximum RPM

using the engine to acrobatics

starting flight when the engine is not working correctly

opening cooling system when the engine is hot

Necessary is:

do routine maintenance according with the instruction

use recommended spare parts only

use recommended fluids

secure engine and components for storage

4.Engine systems

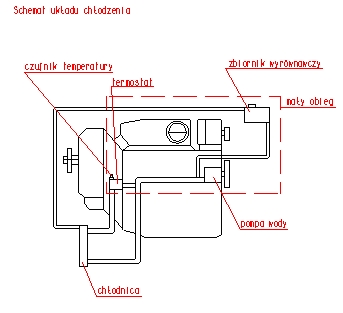

Cooling system.

LS 1000 is water cooled engine. The cooling system is pressured pump-assisted

thermo-sypfon type.

The system consist of the radiator, water pump, thermostat and expansion tank.

Thermostat starts to open at the water temperature between 82-88 ° C.

TEMPERATURE RANGE =90-100°C

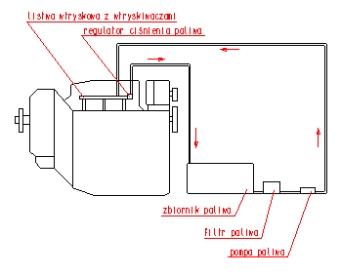

Diagram

Fuel system.

Fuel is inducted from fuel tank through the filter to the injectors. The fuel

pressure controller keeps up fuel pressure between 2,5-3,5 Mpa. Fuel charge is

controlled by computer.

Warning:

- fuel pump must be mounted under fuel level

- fuel pump must be fuel filled

- running the pump without fuel longer than 5 SEC . can cause serious failure

Reduction gear.

The helicoial gear with grinded teeth. Housing is made from light alloy.

The reduction gear is equipped with a dynamic anti vibration damper. It is oil

filled through the top gate (0,2-0,25 ltr.) There is no bottom outlet and level

gauge.

Oil system.

The oil system is pressured type with oil pump driven from crankshaft with full

flow oil filter.

The oil pressure indicator is checking oil pressure. Running engine without

minimum oil pressure can cause serious failure. The minimum oil pressure is 0,1

MPa about 2000 RPM (oil temperature 90 ° C.

TEMPERATURE RANGES

90-110degree centigrad

5.Exploitation and

service.

Starting.

Before start the engine every flight action and safety rules must be checked.

When the engine is cold or air temperature is below 20 ° C switch position

"1" on the computer.

After 5 sec. after starting the engine switch position "0". When the

engine is hot or air temperature is above 20 ° C switch position "0"

on the computer.

ROTARY

REVOLUTION

|

Bilsamaviation

has observing the development of rotary power plants in united

states for last 8 years and has decided to pursue this idea

further and develop the most reliable

power plant for light aviation This seems to be a deviation from

general trend in Europe where high fuel prices have motivated few companies

to develop diesel power plants for the light aviation but according to our

logic the diesel engine will always be heavier and average ultralight pilot

fly about 40-50 hours per year So

really there is very less fuel saving costs, and this can be compensated by

the longer TBO (2500hours and planned to be increased to 3000 hours in near

future) And

fixed general over haul cost of only 1999 euro for our rotary power plants |

|

History

Dr. Felix Wankel invented the engine in 1930 .after 20

years of development and improvements the first prototype was built in 1950

But it was odd looking engine (too futuristic for it’s

time)

And did not created any commercial success

But one company saw the superior kinematics of this

concept and bought the rights of the engine

This was japanese company named Toyo Kogyo or known as

Mazda motors to the world

Mazda created state of art computerized test facility

to further improve the concept and invested millions of dollars and thousand of

hours on rotary concept

After 17 years of long research and development Mazda

started selling cars with rotary engines in 1967

Over the years several engineering challenges were

encountered and lot of lessons were learned from every day use of this engine.

More than 2 millions cars were sold with this engine

in very short period (it took Lycoming and Continental more than 40 years to

sell about 400000 aircraft engines)

In 2003 Mazda introduced new sports car RX 8 with 4th

generation Renesis

rotary engine

This engine is the by product of 37 years of

experience in rotary technology and Bilsamaviation has fully confidence to the

concept. Let’s see why the rotary is perfect choice for aviation.

In aviation the most important factor should be safety not fuel costs (diesel concept)

rotary verses piston engine

Piston engines

In piston engines reciprocating action produces

tremendous stress on the engine parts like connecting rods, pistons, pins,

valves, valve springs, camshafts, lifters push rods, etc

In piston engine parts move, then stop, then up and

down and in all directions twice per revolution

So it’s impossible to perfectly balance the piston

engine

As the parts reciprocate, and oscillate, and they through

off their center of gravity and normal piston engine has about 44 moving parts

,so you can imagine what mess is inside when engine is working let’s

analyze the motion of typical piston engine, rotating at 5000RPM (cruise RPM of

Rotax

912 at 75%power)

The bore is 4 inches

Stroke is 3 inches

At 3, o clock position of the crank, the piston is

moving down the bore at maximum speed

At 9.0 clock position of the crank, piston is moving

up the bore at maximum speed

At 12.o clock and 6, o clock position its stopped at

the top and bottom of the bore

Now stay with me

The circumference of the crank is pi x 5inches

Which is 15.7 inches or 1.31feet

We have cruise RPM of 5000

5000RPM = 84

rps (rev.per second)

Crank pin is moving at

84 x 1.31 =110 feet/second moving in a circle

Piston speed is same as pin speed at 3, o clock and 9, o clock position.

Which means it takes crank1/84 second or 0.0119 seconds to rotate once

Now the rotation of the crank from 12,o clock to 3,o

clock will take one quarter(1/4) of 0.0119 seconds that is 0.0029 seconds

There fore piston accelerated from dead stop to 84

feet per second in only .0.0029

seconds so average acceleration of crank would be,

Crank acceleration=speed of crank insec. /time in

seconds=84/0.0029=28965

feet per second

This is tremendously fast and here is the night mare

We know (i hope)

1g=32 feet/sec. so 28965

feet per second / 32feet per second = 905g,s

Now lets assume that connecting rod, piston pin and

piston with rings weighs about 7 lbs and piston about 3 lbs.

So the inertial load of 3 pound piston to the

connecting rod=3x905=2715lbs=(1123kgs)

So poor connecting rod is pushing 2715 lbs of piston

in every0.0119 second

Then 7 lbs of collected load of connecting rod, piston

pin, piston with rings is exerting inertial load on the crankshaft=7x905 =6335lbs =(2879kgs)

So it’s only the miracle of metallurgy science and

almost 100 years of work and billions of dollars spent by auto industry that

the piston engine last so longer

But aviation is high risk business/hobby

And we can see the piston engines are very prone to

damage and any small minor maintenance problem/negligence can lead to engine failure

They last longer in the cars as they are working at

about 30% of the power

but in aviation we need 65%to 75%

the power

That's why Lycoming and Continental have stayed to

large displacement low RPM engines

(high RPM means, very high inertial loads on the parts)

but they are left behind as they have not modernized their engines with fuel

injections, water cooling and other high tech

goodies

Rotary

engine

Rotary

engines are not reciprocating engines, every parts move in a circle or in same direction

There

are only 3 moving parts,

not 44 to 46 as compared to piston engines

There

are no exhaust valves to melt or burn (in piston engine 80% of the engine failures are caused

due to exhaust valves problems)

These

poor valves run at extremely hot temperature's and opening and closing

about 1200-1500 times

per minute

Their

is no cam shaft to worry about in rotary as there isn't any Rotaries are

perfectly balanced just like turbine or electric motors

In rotary propeller gets 6 power impulses per

revolution which means it will take piston engine to have 12 cylinders to

have same smoothness as twin rotor, rotary engine

Best thing is rotary never fails like pistons engine

You

may lose partial power if you loose your coolant and

you will still have some power to get to the nearest landing place

misconcepts about rotaries engines

1. 2 stroke engine

Lot of people think its 2 stroke engine which

is not truth

It has four cycle like

1) intake

2) compression

3) expansion

4) exhaust

And

it fires twice per output shaft revolution

2. High fuel consumption

That

was true for the early models but new RX 8 engine has fuel burn very close to

today's modern piston engines as RX 8 has now side exhaust ports and any

residual un burned fuel is recirculated to next combustion cycle. The

exhaust port timing has been modified and RX 8 has lower exhaust temperatures

confirming the low fuel consumption

3. High oil use

The main reason for the high

oil use in the early models was the quick wear of the rotar seals, this problem

has been fixed by new ceramic silicon carbide seals and they are 700% stronger

than metal seals

4. Complicated engine

This reason is really very astonishing as really their

are no complication in construction,

lot of people do not under stand the engine and

they stamped it complicated engine

then why sky is not full with

rotary engine powered aircraft's?

Good

question or why Mazda does not certify this engine for

aviation use

The

main reason is commercial

As

aviation is such small market for Mazda and second they will never allow any

aviation authority to dictate them what to do or not as when you certify the

engine you have to go for very long and tiring procedure of approvals for any

small modifications and i think Mazda do not want to have this

headache, so here comes Bilsamaviation in the picture

Engine

itself is not a problem

To

convert the engine for aviation use following engineering challenges have to

be solved

- Custom

made oil pan

- Custom

made exhaust system

- Custom

engine mount

- Custom

cooling ducting and plumbing

- Proper

cowl design to prevent back pressure lock on the radiator so you do not

get the heating problems

- Modified

water pumps inlets and out lets

- Modified

intake manifold

- And

most important, reliable gear reduction unit

Bilsamaviation

has taken up these challenges and developed the perfect light and reliable engine

for aviation use

Advantages

1. compact

2. high power to weight ratio

3. 2500 hours TBO as compared to 1200 to other piston engines

4. very low fixed over haul cost of about 19999 euros

5. reliability

6. simple

7. smooth like electric motor

8. high damage tolerance

9. low purchase cost

10. spare parts backed by one of the world's biggest company (Mazda

motors)

11. low cost auto fuel operation

Performance specifications

|

Engine type |

|

Rx8-SR |

|

Rx8-XP |

|

Rx8-TR |

|

|

|

|

|

|

|

|

|

All up dry weight |

|

68,9 kg |

|

68,9 kg |

|

120 kg |

|

Horse power |

|

100 hp |

|

120 hp |

|

240 hp |

|

Maximum RPM |

|

7500 |

|

8000 |

|

7500 |

|

Cooling |

|

Water &

oil cooling |

|

Water &

oil cooling |

|

Water & oil cooling |

|

Displacement |

|

650 cc |

|

650 cc |

|

1300 cc |

|

Maximum torque |

|

125 nm @ 4500 RPM |

|

140 nm @ 4500 RPM |

|

“ |

|

Reduction ratio |

|

3:1 |

|

3:1 |

|

3:1 |

|

Alternator |

|

24 amp |

|

24 amp |

|

30 amp |

|

Fuel consumption |

|

15 liters |

|

18 liters |

|

25 liters |

|

Fuel system |

|

Multi part fuel injection |

|

Multi part fuel injection |

|

Multi part fuel injection |

|

Compression ratio |

|

10:1 |

|

10:1 |

|

10:1 |

|

Transmission type |

|

Helical type gear with dynamic

vibration damper |

|

Helical type gear with dynamic

vibration damper |

|

Helical type gear with dynamic

vibration damper |

|

Transmission oil |

|

Sae 85 w 90-api-gl4 |

|

Sae 85 w 90 api-gl4 |

|

Sae 85 w 90 api-gl4 |

|

Lubrication system |

|

Wet sump Oil pump |

|

Wet sump Oil pump |

|

Wet sump Oil pump |

|

Fuel |

|

95 or higher octane |

|

95 or higher octane |

|

95 or higher octane |

|

TBO |

|

2500 hours |

|

2500 hours |

|

2500 hours |